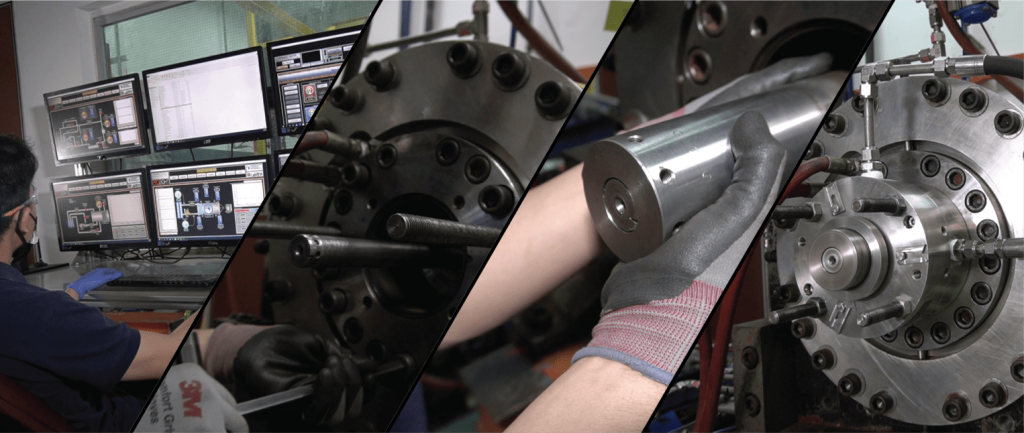

Testing Facilities

Ensuring Peak Performance: ProEight's Advanced Testing Facilities

At ProEight, we understand the critical importance of equipment reliability and safety. That’s why we’ve invested in state-of-the-art testing facilities featuring a comprehensive suite of industry-leading equipment, including AccuTEST, AccuDYN, and AccuFLOW. These advanced tools allow us to rigorously evaluate the performance of your equipment, guaranteeing it meets the world’s demanding standards.

AccuTEST

AccuDYN

AccuFLOW

ACCUTEST: Seals Assembly Integrity Test API 682 4th Edition Clause 10.3.4

As stipulated in the guidelines, new or repaired cartridge seals assembly shall be tested in pressurized air or nitrogen prior to shipment. Conventionally, the test parameters are observed and recorded manually, and the accuracy depends on the testing personnel.

Being an API Q1 accredited company, ProEight abides by and comply with the requirements.To ensure the highest standards of quality and integrity, we have developed and patented a testing apparatus; Mechanical Seal Static Air Test Apparatus.

Patent No: WO2012050432A3.

Being an API Q1 accredited company, ProEight abides by and comply with the requirements.To ensure the highest standards of quality and integrity, we have developed and patented a testing apparatus; Mechanical Seal Static Air Test Apparatus.

Patent No: WO2012050432A3.

Play Video

Parameter

Seal Type

Single Seal

Double Seal

Tandem Seal

Double Seal

Tandem Seal

Seal Size

Up to 14 inch

Maximum Running Pressure

35 psi

ACCUDYN: Mechanical Seals Dynamic Tester

Being an API Q1 accredited company, we understand the importance of a quality standard. We are passionate about providing the ultimate experience in mechanical seals solution to our clients.

ProEight’s Mechanical Seals design has undergone extensive engineering design and development process and a qualification test for validation purposes. Apart from the internal testing requirement, we are also extending this testing facility to our client on a request basis.

ProEight’s Mechanical Seals design has undergone extensive engineering design and development process and a qualification test for validation purposes. Apart from the internal testing requirement, we are also extending this testing facility to our client on a request basis.

Additional testing services available :

- Dynamic Test

- Hydrostatic Test

- Design Verification Test (other brands)

Play Video

Parameter

Seal Type

Single Seal

Double Seal

Tandem Seal

Double Seal

Tandem Seal

Seal Size

14 Inches (Shaft) & 11.25 Inches (Gland)

Maximum Running Pressure

100 bar

Maximum Temperature

100 Celcius

Maximum Pump Speed

3,600 rpm

ACCUFLOW: Pump Performance & Functionality Test

The purpose of pump performance test is to obtain the performance characteristics of a centrifugal pump.

The performance curves obtained will include pump head, power input & efficiency as a function of flow rate for different pump speeds.

The performance curves obtained will include pump head, power input & efficiency as a function of flow rate for different pump speeds.

Additional testing services available :

- Dynamic Test

- Hydrostatic Test

- Design Verification Test (other brands)

Play Video

Parameter

Type of API 610 Centrifugal Pump

OH1 to OH6 (overhung pump) & BB1 to BB5 (between-bearing pump)

Pump Size

Up to 12 inch

Maximum Testing Operating Pressure

85 bar (runningtest) & 200 bar (hydrostatic test)

Maximum Flow Capacity

1,500 m³/hr

Maximum Driver Power

200kW

Maximum Driver Speed

3,000rpm at50Hz & 3,600rpm at 60Hz